JLLM立式磨粉機

FLOWCHART OF JLLM VERTICAL ROLLER MILL PROCESS

JLLM立式磨粉機工藝流程示意圖

LSM系列超細立式磨粉機是金侖公司以幾十年的生產經驗為依托,吸取德國、日本、中國臺灣超細立磨技術,并采用優質的耐磨配件,研發出的集破碎、粉碎、分級輸送于一體的磨粉行業的理想設備。設計技術團隊與國內高校機械科研團隊合作,超細立磨的成品細度最高可高達500目。

LSM超細立磨設備,廣泛應用于碳酸鈣、滑石、鐵粉、炭黑、膨潤土、鉬粉、石灰石、硅灰石、白云石、云母、超細水泥、電力、冶金、化工等行業。用于將塊狀、顆粒狀及粉狀原料磨成所要求的的粉狀物料。

LSM series ultra-fine vertical mill is developed by Jinlun Company, based on decades of production experience and absorbing the technology of ultra-fine vertical mill from Germany, Japan and Taiwan, China as well as adopting high-quality wear-resistant accessories. It is developed to be an ideal equipment in the mill industry, which integrates the functions of crushing, shattering and grading transportation. The technical design team cooperates with the mechanical research team of domestic universities. And the maximum fineness of the finished products of ultra-fine vertical mill can reach XXX.

LSM series ultra-fine vertical mill is widely used in calcium carbonate, talc, iron powder, carbon black, bentonite, molybdenum powder, limestone, wollastonite, dolomite, mica, ultra-fine cement, electricity, metallurgy, chemical industry, etc. It is used for grinding blocky, granular and powdery raw materials into the powder materials meeting the requirements.

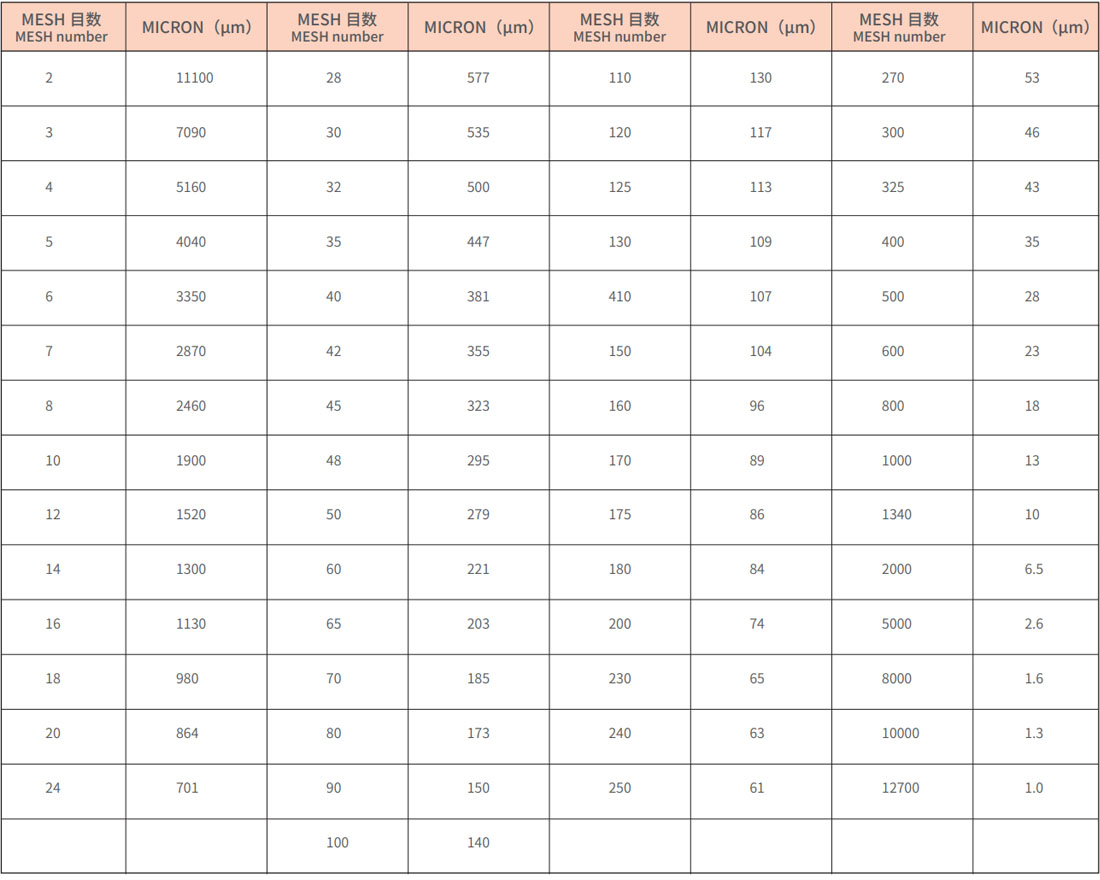

工作原理/ OPERATING PRINCIPLE

電動機通過減速機帶動磨盤轉動,物料經喂料器從進料口落在磨盤中央。隨著磨盤的轉動,物料在離心力的作用下,向磨盤邊緣移動,經過磨盤上的環形槽時受到磨輥的碾壓而粉碎,粉碎后的物料在磨盤邊緣被高速氣流帶氣,大顆粒直接落在磨盤上重新粉磨,氣流中的物料經過上部分離器時,在旋轉轉子的作用下,粗粉從錐斗落到磨盤重新粉磨,合格細粉隨氣流一起出磨,通過收塵裝置收集即為產品。通過調整分離器,可達到不同的粗細度。

The motor drives the millstone to rotate through the reducer, and the materials fall into the center of the millstone from the feeding inlet through the feeder. As the millstone rotates, the materials under the action of centrifugal force move to the edge of the millstone and are crushed by the grinding roller when passing through the annular groove of the millstone. The crushed materials are carried by high-speed air flow at the edge of the millstone, and large particles directly fall on the millstone for regrinding. When the materials in the air flow pass through the upper separator, the coarse powders fall from the cone bucket to the millstone for re-grinding under the action of the rotating rotor. The qualified fine powders are ground together with the air flow and collected by the dust collector, becoming the products ultimately. By adjusting the separator, different roughness parameters can be achieved.

技術優勢/ TECHNICAL ADVANTAGES

比表面積20000±1000cm2/g、d97=8.5um產品可有JLSM-1150立式磨粉機產出。

Specific surface area is 20,000±1,000cm2/g, d97=8.5um. Products can be produced by JLSM-1150 vertical roller mill.

研磨:原料被輸送入主機后,底部磨盤轉動的離心力,將原料向外推送至磨輪之間進行研磨,三個磨輪均有單獨的油壓連桿控制研磨壓力,油壓系統輸出的恒定壓力為65~75kg/cm2,使原料于三個磨輪于磨盤之間進行研磨,油壓系統配備有六個蓄壓器可吸收顆粒狀原料初步粉碎時所產生的出來的振動力。

Grinding: After the raw materials are transported to the main engine, the centrifugal force of the bottom millstone pushes raw materials outward the area between the grinding wheels for grinding. Each of the three grinding wheels has an individual hydraulic connecting rod to control the grinding pressure. The constant pressure output by the oil hydraulic system is 65-75kg/cm2, so that the raw materials are ground between the three grinding wheels and the millstone. The oil hydraulic system is equipped with six accumulators to absorb the vibration force generated when the particle raw materials are ground preliminarily.

分級:原料于磨輪和磨盤之間研磨成細粉之后,自磨盤周圍溢出,隨著環帶狀氣流上升,進入上端的轉動錐形分級葉片區,經過分級葉片區較粗的粉無法通過以設定轉速分級的葉片區,而直接落在下部繼續研磨,通過分級葉片區的粉末稱為細粉,這些細粉將被收入后段集塵裝置中。依成品要求細度,可以選擇配裝雙層葉扇式分級葉片(粗粉),錐形鋁合金分級葉片(細粉)或復合式平轉分級輪(超細粉)等不同的分級裝置。

Classification: After the raw materials are ground into fine powders between the grinding wheels and the millstone, they overflow from the periphery of the millstone and enter the rotating conical grouped blade area at the top as the annular air flow rises. The coarser powders passing through the classified blade area cannot pass through the blade area classified at the set rotation speed, but directly fall on the lower part, continuing to be ground. The powders passing through the classified blade area are called fine powders, which will be collected into the dust collector at the rear section. According to the fineness required by the finished product, different classification devices such as double-layer blade-size classifying blade (coarse powder), tapered aluminum alloy classifying blade (fine powder) or composite horizontal rotation stepped gear (ultra-fine powder) can be selected.

氣流:細粉隨著氣流通過分級葉片后,進入脈動式袋濾器中,集塵裝置收集細粉后,被分離的空氣會由風車再次進入系統中,氣流于整個系統中呈負壓狀態。因此,消除了由于粉塵的散溢而引發污染環境的問題。若是原料潮濕可加熱氣流加熱裝置,可以使干燥和研磨同時進行。

Airflow: After the fine powder passes through the classified blade with the airflow, it enters the pulse bag filter. After the dust collecting device collects the fine powder, the separated air will be carried out in the system again through the windmill, and the airflow will be in a negative pressure state in the whole system. Therefore, the problem of environmental pollution caused by dust overflow is eliminated. If the raw material is moist, the air flow heating device can be heated. And the drying and grinding can be carried out simultaneously.

控制:經由plc編程式工程機及多種控制元件安裝于電器控制盤上,如電流控制器、機負載控制器、變頻器及警報裝置等遠程式控制器連線,系統全自動運轉于最佳效率的生產狀態。

Control: Through programmable touch man-machine and various control components installed on the electrical control panel, such as current controller, machine load controller, frequency converter, alarm device and other remote controllers connected, the system operates fully automatically in the production state with the best efficiency.

立式磨粉機參數1

立式磨粉機參數2

新型立式滾輪磨粉機設備型號:JLLSM-1150

New Vertical Roller Mill Equipment Model: JLLSM-1150

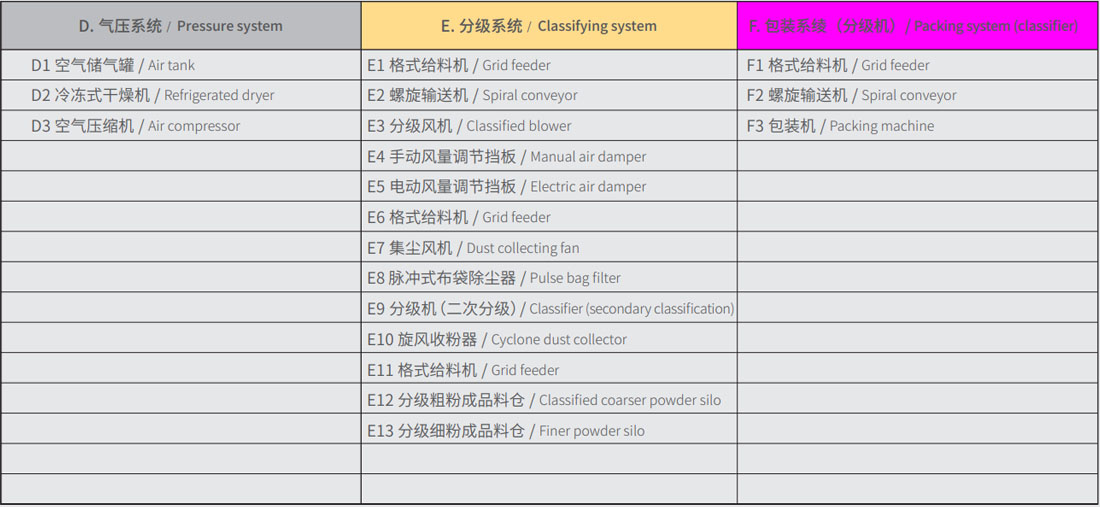

生產重質超微細碳酸鈣物理化學試驗一覽表

List of Physical and Chemical Tests for Producing Heavy Micro-Fine Calcium Carbonate

立式磨粉機參數3

JLLSM-1150立式滾輪研磨機,研磨石灰石之產品、規格及運轉數據

Data of Products, Specifications and Operation of JLLSM-1150 Vertical Roller Grinder for Grinding Limestone

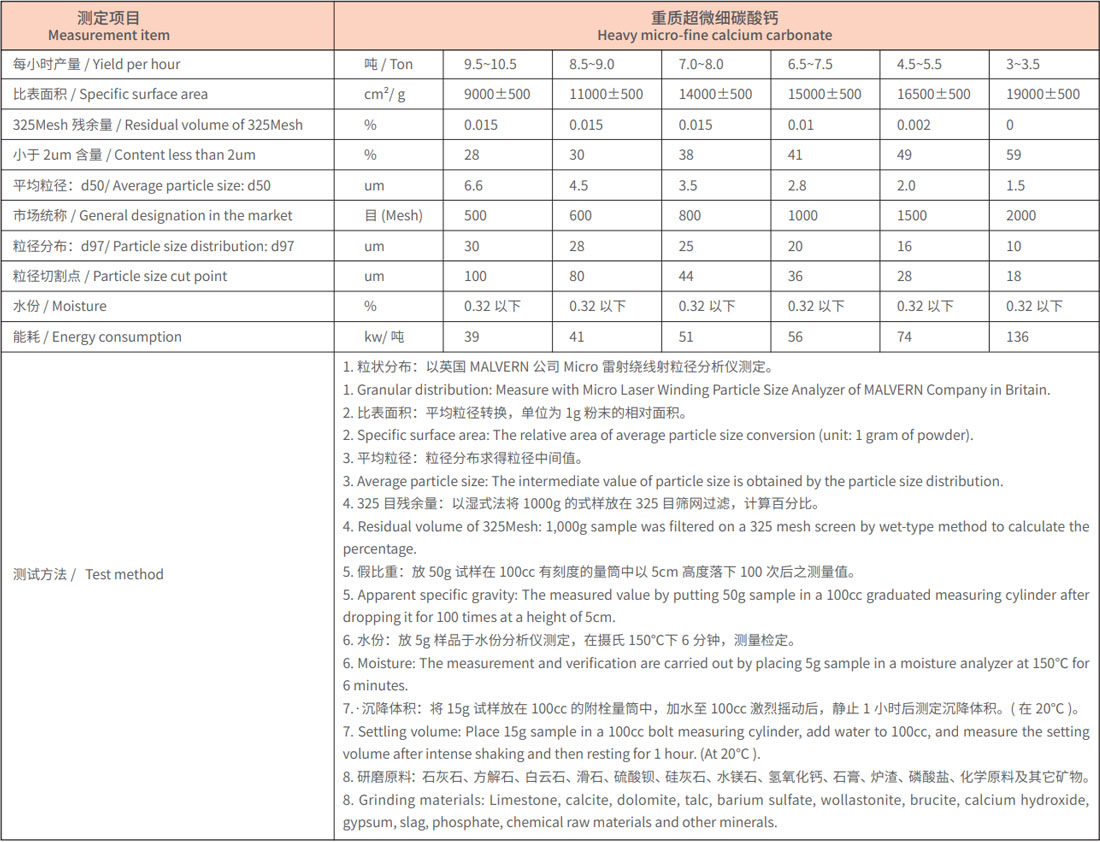

標準篩網比較表Comparison Table of Standard Screen Mesh

立式磨粉機參數4

施工案例? ? ? ?公司環境

新聞資訊? ? ? ?聯系我們

電話:136 0412 4805

傳真:0412-3214 668

地址:遼寧省鞍山市海城市響堂街道

大盤線紅光工業園區

網址:jinlunmach.com